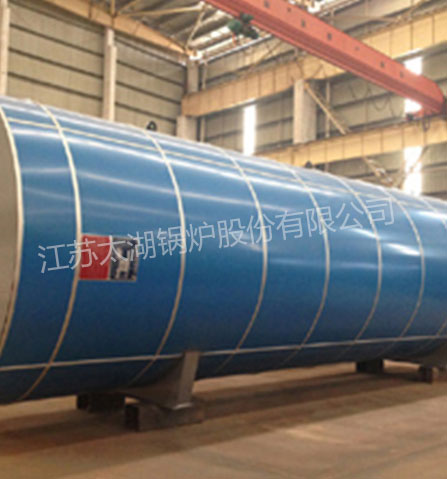

The organic heat carrier boiler uses bituminous coal, light oil, heavy oil, combustible gas waste wood, sanding powder as fuel, heat transfer oil (conducting) as the heat carrier, and uses a circulating pump to force the heat transfer oil to circulate in a liquid phase, and then heat energy After being conveyed to the heating equipment, it returns to the heating furnace to reheat the direct-flow special boiler.

Features:

1. It can obtain a working temperature below 350℃ under a lower operating pressure, and has the technical characteristics of low pressure and high temperature;

2. Stable heating and precise temperature adjustment can be realized, and the quality of heating products can be improved;

3. Perfect operation control and safety detection device, easy to operate, safe and reliable;

4. Closed loop, liquid phase transportation of heat energy, low heat loss, significant energy saving effect, and good environmental protection effect;

5. Equipped with water pipe waste heat steam boilers and steam generators to realize dual use in one boiler, with significant energy-saving effects.

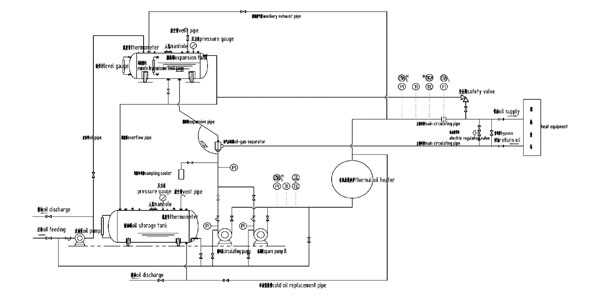

Process flow chart of organic heat carrier boiler: